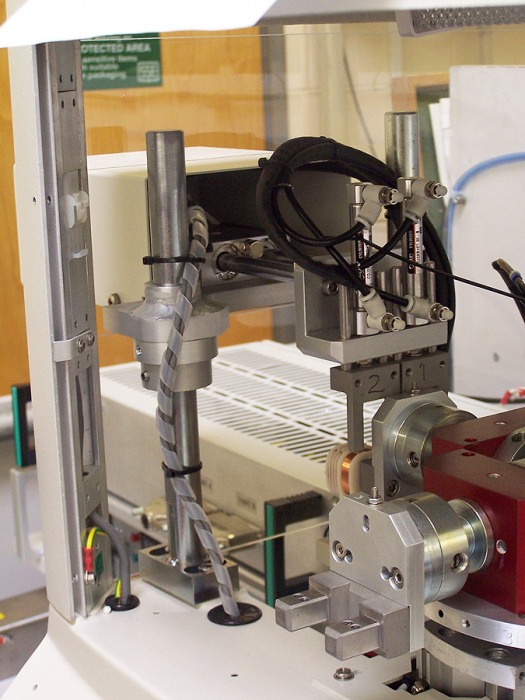

A versatile rotary bench top soldering machine ideally suited for high or low volume production, the Cadet, combines well proven soldering techniques with advanced microprocessor technology. Much of its versatility is owed to the specially designed programming system which allows the user access to all fluxing and soldering parameters, in addition, rapid product change-over is achieved quickly and easily through simple tooling design and program identification.

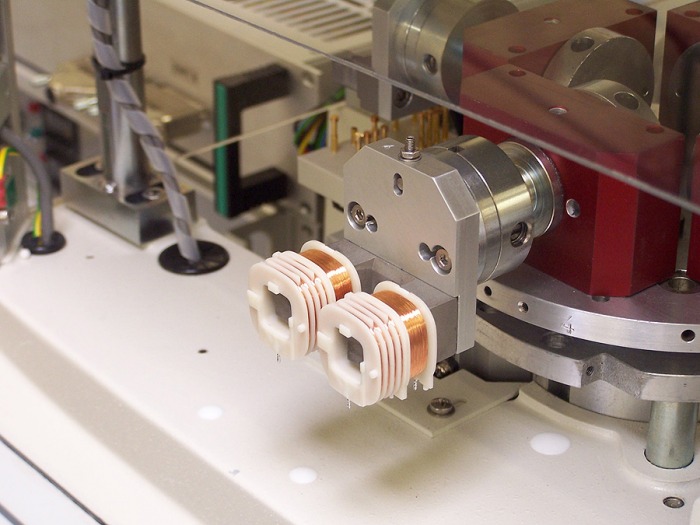

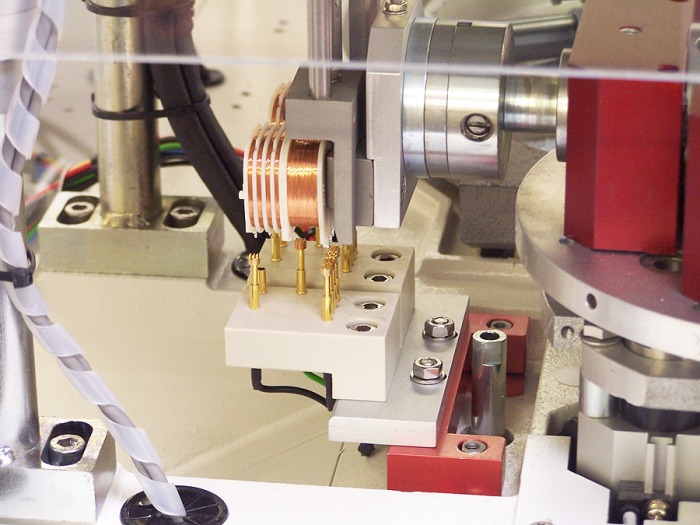

Fluxing System

Using the same system as in the soldering process, flux is applied to the terminals via a crucible which provides high quality and consistent repeatability. Flux application is of paramount importance, this is where the Cadet has an advantage, as it is able to control the application and avoid bobbin contamination by applying flux accurately. Excess flux and insulation residue is kept to a minimum by careful control of the dip height and immersion time, this being achieved through a microprocessor and stepper drive motors.

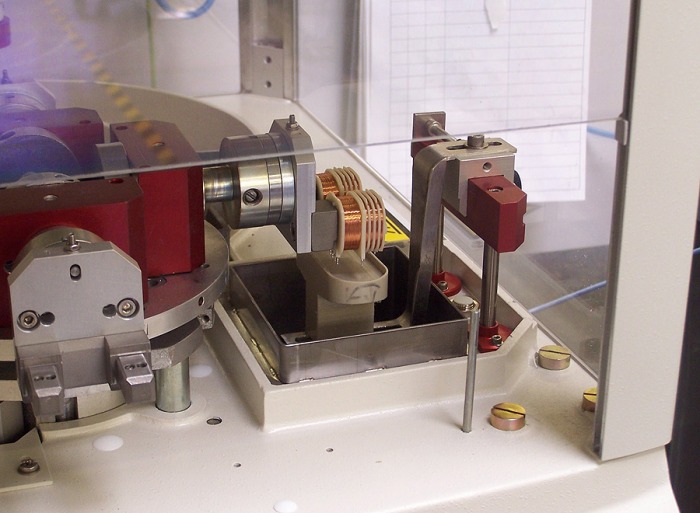

Soldering

The Cadet uses a simple reliable static system which provides clean solder at a constant level and volume therefore offering repeatable high quality soldered joints each and every operation. A crucible or applicator (which can be product specific if required) is lifted from the molten bath of solder to immerse the component terminations into the applicator to a precise depth and for a controlled time period. Any contaminants or dross are directly removed from the surface of the solder by a unique double wiping cleaning system immediately prior to the soldering action. The solder temperature is controlled by a processor and offers the user the ability to heat the solder up to 500°C offering the opportunity to use both high and low temperature solders.

Programming

The Cadet can be quickly and easily programmed to solder a wide range of different products e.g., coils, transformers, wire terminations and small PCB’s. The machine has a memory for up to 49 programmes and the fluxing and soldering parameters are entered via a keyboard, to give full control of: solder bath temperature (to within ±5°C), flux and solder dip heights (increments of 0.1mm), and flux and solder immersion time (to within 0.1 of a second). Additional operations can also be controlled e.g. component test facility, component unload and adjustment of the cycle time etc. A twenty-four hour wake-up timer is included as standard equipment which enables the machine to be automatically powered-on and bought up to temperature prior to the start of a working shift.

System Options

The Cadet, a highly versatile machine can be made more so by the addition of various optional equipment, some options are listed below.

Turnover

The optional turnover facility enables components with terminals on opposing sides to be handled on the same tooling with fluxing and soldering performed at the same time without the need for the component to be re-loaded. Also, if a component has different soldering requirements on each side the Cadet will identify the different programming parameters.

Automatic Test/Unload

Optional test and / or unload facilities offer the ability for components to be tested for electrical continuity or resistance prior to the component being automatically or manually ejected / unloaded as a pass or fail.

Flux Density Controller

This option is a separate standalone machine and is located on the floor adjacent to the Soldering machine; it controls the viscosity of the flux and maintains it at the correct specific gravity. The FDC is connected to the soldering machine and continually re-circulates the flux between itself and the flux tank in the machine. On the return to the FDC the flux passes by a Hydrometer which monitors its viscosity, if it becomes too dense, thinners is added until the right consistency is acquired.

Specifications