The Pillarhouse Drop-Jet head can be used to spray fluids at any angle in either upward or downward directions.

With its patented easy bleed and cleaning feature it is ideal for automation use. The head comes complete with a hand control unit which allows the operator to fully program the spray head.

The spray function and length of spray duration are both fully programmable at intervals in milliseconds. The controller can be triggered by 24V or RS232 interface.

The PillarDOT system can also be supplied as part of an X,Y axis unit with conveyor transfer.

Wide ranging use applications include solar cell, medical and electronic applications.

Optional Extras

An off-line process programming system

Product Description

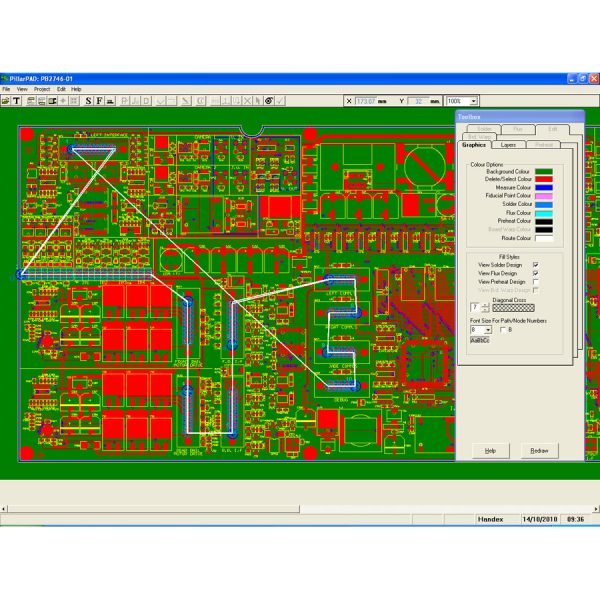

PillarPAD is the Windows® based Off-line Programming system for the Pillarhouse International range of Selective Soldering Systems. It provides a user-friendly interface to allow the User to produce Process Programs away from the Production line. This results in reduced downtime for the production line when configuring for a new product.

PillarPAD is a two-part software package:

PillarPAD Import

PillarPAD Draw

The PillarPAD software package creates a single data file that can then be transferred to the required Selective Soldering System(s). One process program can be used on multiple Soldering Systems.

PillarPAD is available in two licensed formats

PillarPAD is compatible with XP®, Vista® , Windows7®, Windows8® and Windows10®.

The PillarGEN Nitrogen generation system has been specifically designed to meet the Nitrogen supply requirements of the current range of Pillarhouse selective soldering systems.

The latest Nitrogen generation design technology combines compact size with ultra-quiet operation.

The PillarGEN-30 is specifically designed to integrate with the Pillarhouse Pilot bench top soldering system.

The PillarGEN-40 and -80 systems offer a fully integrated communication protocol to allow the monitoring and displaying of the unit’s status on the selective soldering machine. These values include oxygen concentration, flow rates and pressure – incoming air/outgoing Nitrogen.